SLA & SLS Rapid Prototyping Services

MEMSEM Prototype provides professional custom 3D printing services, also known as additive manufacturing, to bring your designs to life. Our process builds parts layer by layer from digital models, perfect for rapid prototyping and low-volume production.

We utilize several advanced technologies to meet diverse needs:

-

SLA (Stereolithography): Ideal for high-accuracy prototypes with smooth surface finishes.

-

SLS (Selective Laser Sintering): Excellent for durable, functional parts without the need for support structures.

-

FDM (Fused Deposition Modeling): A cost-effective solution for larger concept models and functional testing.

-

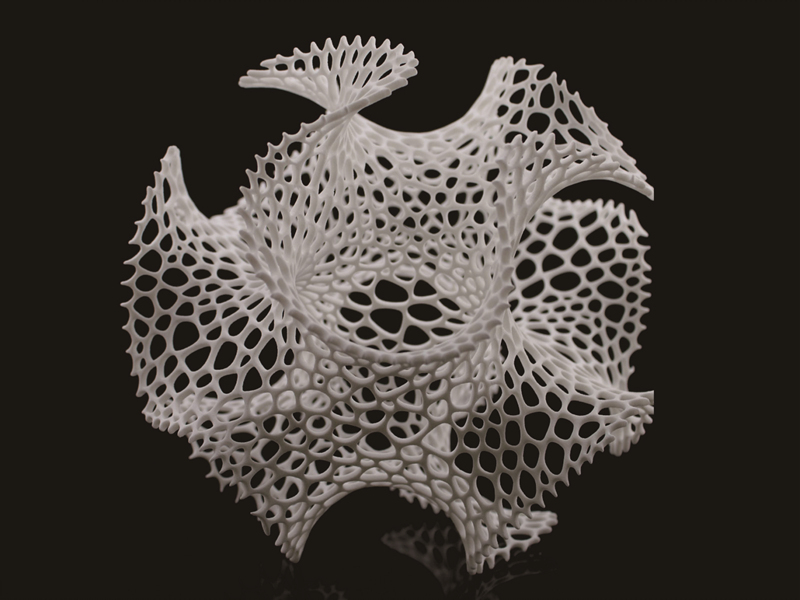

3D Printing (object)

-

3D Printing is an ideal process used in rapid prototyping parts for engineering tests and next-generation products as well as art pieces and architectural models. There are several different 3D Printing processes and a variety of materials to choose from.

-

Tolerances

-

SLA and SLS models typically have layer thicknesses of + .3mm with a lateral deviation of + .1mm. Finer tolerances than this can easily be achieved with post machining per customer requirements. Please see here for more information on the tolerance guide for plastic materials.

For engineering-grade parts, we also offer metal 3D printing options. All processes require 3D model files in standard formats like .STL. The prototypes created through our services can be used for rigorous engineering testing or as master patterns for creating vacuum casting molds. Ready to Start Your Project?

[Contact our additive manufacturing experts today] for a free consultation and quote.

Our Capabilities

-

3D Printing (FDM)

-

The way in which 3D printing has developed in recent years is nothing short of astounding, one of them being FDM 3D printing. This FDM technology is most common and is also known as Fused Deposition Modeling. This is a technology that has been patented by Stratasys and it is a technology that enables the creation of prototypes in a very short timeframe. This technology is also known as Fused Filament Fabrication or FFF 3D printing.

-

Stereolithography (SLA)

-

SLA prototyping is one of the earliest 3D printing methods. It uses a UV light to cure a photopolymer, such as ABS and layer-by-layer, making a durable plastic solid with good resolution of detail. SLA is typically not fast but it wastes little material and it can be used "as is" or as a master mold for a polyurethane vacuum casting. SLA printers were traditionally out of financial reach for most people. Rather than feeding the printer with plastic filament on a spool for heating, photopolymer liquid resin is poured into a vat located within the unit. Photopolymer resins harden when exposed to lasers or light. As the build platform moves downward into the resin tank, the exposed resin is hit by built-in lasers "painting" and the objects cross-section layer by layer.

-

Selective Laser Sintering (SLS)

-

SLS or Selective Laser Sintering is a 3D printing technology that relies on a laser to melt and solidify layers of plastic, metal, ceramic, glass or other materials into layers, in a 3D dimensional structure. Like any other 3D printing technology, the object is being built from the bottom up, as the laser traces the pattern of each cross-section of the object onto a bed of powder. Once the layer is built, the platform lowers so that the next layer can be created. However, unlike most other technologies, SLS does not require supporting structures. When using SLS, there is no chance of the object falling apart. While the platform, holding the object moves down to make space for another layer, the bed of powder goes up, where the next layer will appear and this bed of powder itself, provides for the stability of the printed object. At top of the first layer, another layer of powder is spread by a roller. The ability, to create new layers without the possibility of damaging the whole object, allows this technology to build much complex 3D objects than any other machine such as complex interior components and complete parts. This 3D technology is also saving a lot of time because there is no need to clean the tools or the object from any supporting materials.

Thank you for your attention to our service. In order to better serve you, please fill in the information. We will reply to you within 24 hours. Sincerely hope to serve you!