Memsem Prototype is a leading supplier providing high-quality CNC machining services with fast turnaround and precision engineering.

MEMSEM Prototype is a leading supplier providing CNC machining services and EDM machining services. We can manufacture parts using any kinds of material. We offer a wide selection of engineering plastics, alloys, and other exotic materials. We use high speed and high precision CNC machines to deliver parts, typically within 3 to 5 days. Our skilled technicians can thread holes complying with International (Metric) or US (Imperial) standards.

MEMSEM Prototype is a leading supplier providing CNC machining services and EDM machining services. We can manufacture parts using any kinds of material. We offer a wide selection of engineering plastics, alloys, and other exotic materials. We use high speed and high precision CNC machines to deliver parts, typically within 3 to 5 days. Our skilled technicians can thread holes complying with International (Metric) or US (Imperial) standards.

CNC machining is suitable for making plastic and metal parts. CNC machining can finish production from one single prototype to up to 500 parts. A wide variety of materials can be machined, including mild and stainless steel, aluminum, magnesium, zinc, brass, and various kinds of plastics.

At MEMSEM Prototype, we use state-of-the-art CNC Machines. We offer 3 Axis, 4 Axis, and 5 Axis operations for a selection of engineering plastics and alloys. Our precision standard tolerance is ± 0.05 mm.

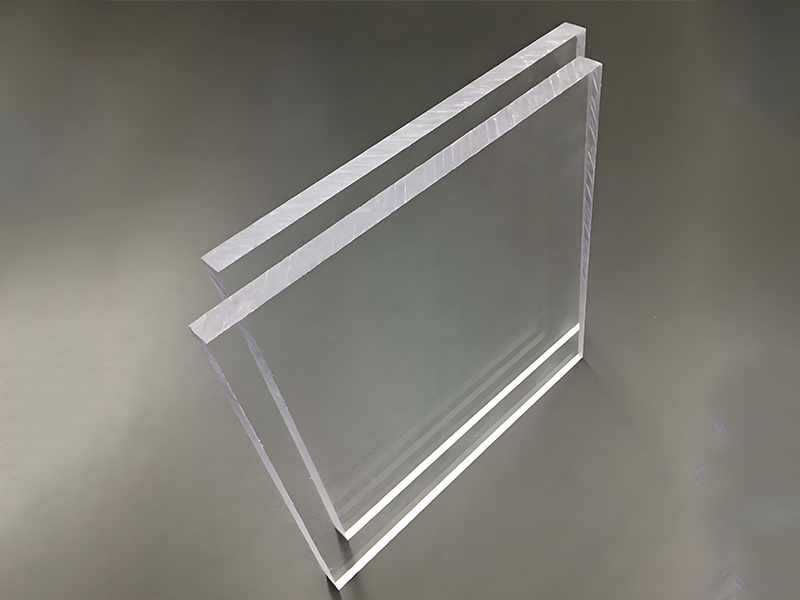

Transparent components are primarily used for display areas, light-transmitting sections, and many products also employ them for decorative effects. For prototype transparent parts, PMMA (acrylic) and PC are generally the two material choice

Inquire Now

Aluminum alloy parts with simple structures: For hardware components that are relatively simple in structure, small in size, have standard precision requirements, and involve small quantities, such as common small hardware connectors, the processing for

Inquire Now

In the product development process, the rapid manufacturing of handboard models plays a crucial role in design verification, functional testing, and market promotion. CNC rapid handboard model technology, with its high precision and high efficiency, has b

Inquire Now